Your reliable source for top-tier aviation consumables from 18 Years.

Aircraft Sealants & Adhesives

Trusted Partner for Aircraft Sealants & Adhesives

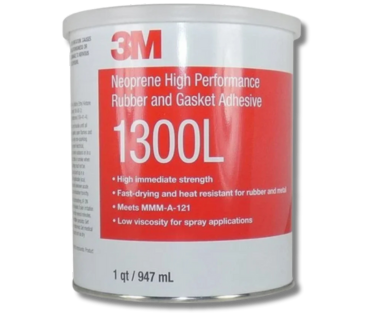

Aircraft sealants and adhesives are essential for ensuring structural integrity, leak prevention, and durability in aviation applications. Designed to withstand extreme temperatures, pressure differentials, and chemical exposure, these products play a critical role in maintaining aircraft safety and performance.

At Team Aviation, we supply high-performance sealants and adhesives from leading OEMs, tailored for aerospace applications. Whether for fuel tank sealing, aerodynamic smoothing, or structural bonding, our products provide unmatched adhesion, flexibility, and resistance to harsh environmental conditions.

1.png)